|

|

|

Operation and Maintenance Instructions Click

here for a full cut sheet |

|

Features and Benefits:

|

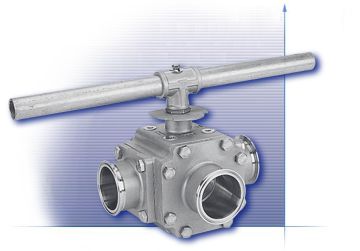

The 507F is a true multi-way ball valve with balanced 4-seat construction which can reduce the number of process valves required in a piping system. This full port valve is available in a number of flow configurations with both clamp and tube O.D. butt weld end connections. |

|

Operating / Test Conditions:

|

|

|

Options:

|

(TFM Seats)

|

|

|

Material | Qty |

|

|

Body | A351 Gr. CF8M | 1 |

|

|

End Cap | A351 Gr. CF8M | 3 |

|

|

Blind End Cap | A351 Gr. CF8M | 1 |

|

|

Ball | 316SS | 1 |

|

|

Stem | 316SS | 1 |

|

|

Seat | TFM | 4 |

|

|

Body Seal (small) | TFM | 3 |

|

|

Body Seal (large) | TFM | 1 |

|

|

Thrust Washer | PEEK | 1 |

|

|

Stem Packing Set | TFM | 1 |

|

|

Packing Gland | 304SS | 1 |

|

|

Belleville Washer | 301SS | 4 |

|

|

Gland Nut | 304SS | 1 |

| 14 | Gland Nut lock Washer | 304SS | 1 |

| 15 | Stop Plate | 304SS | 1 |

| 16 | Stop Pin | 304SS | 1 |

| 17 | Handle Drive Coupling | 304SS | 1 |

| 18 | Pipe Handle | 304SS | 1 |

| 19 | Handle Bolt | 304SS | 1 |

| 20 | Stem Bearing | PEEK | 2 |

| 21 | Body Bolt | 304SS | 20 |

| 22 | Body Bolt Washer | 304SS | 20 |

| 23 | Seat Housing | 316SS | 4 |

| 24 | Seat Housing O-Ring | Viton 90 | 4 |

| 25 | Stem Set Pin | 316SS | 1 |

| 26 | Trunnion Bearing | PEEK | 1 |

| 27 | Trunnion Seal | PEEK | 1 |

| 28 | Trunnion | 316SS | 1 |

| 29 | Trunnion Bolt | 304SS | 4 |

| Size | L | M | P | H | H1 | H2 | H3 | D | d | S |

ISO

5211 Pattern

|

Weight (lbs) | |

|

CL

/ BW

|

EW

|

||||||||||||

| 3 | 10.51 | 12.00 | 22.00 | 2.91 | 7.45 | 3.11 | 2.38 | 0.89 | 4.02 | 0.34 | 0.87 | F10 | 52.17 |

| 4 | 12.48 | 14.00 | 32.00 | 3.78 | 8.20 | 3.86 | 2.34 | 0.84 | 4.02 | 0.34 | 0.87 | F10 | 90.23 |

Due to continuous product development, information may change without notice.